How to improve and better estimate order-volume to reduce wastage?

Sprintly

SprintlyProblem

BeverageCo. a nordic leader in the beverage market. BeverageCo. was struggling with its inventory ordering process since it was being done manually in conjunction with the ERP recommendation. But this was leading to frequent over-and-under orders, leading to high wastages and low service levels.

BeverageCo. sought to improve this process and calculation. The SprintlyWorks team assisted BeverageCo. in developing a new order estimation tool and automating its ordering process.

Our Approach

SprintlyWorks team conducted a three-phase development sprint, to create an ordering estimation tool.

Phase 1: Understand the demand characteristics of each product

In order to understand the characteristic of demand for selected products, the team analyzed the current sales forecast model. Then listed the required lead times for customers, warehouse as well product shelf life as well as other factors such as cost of lost sales, SLAs, probability of meeting demand.

This helped define the criteria for the new inventory model.

Phase 2: Calculate the inventory levels for each product

Inventory levels were defined through two distinct approaches:

Static Model: This model was based on the industry-wide Economic Order Quantity (EOQ) standards. This approach was utilised for estimating the order quantity and safety stock levels of non-critical products, such as accessories.

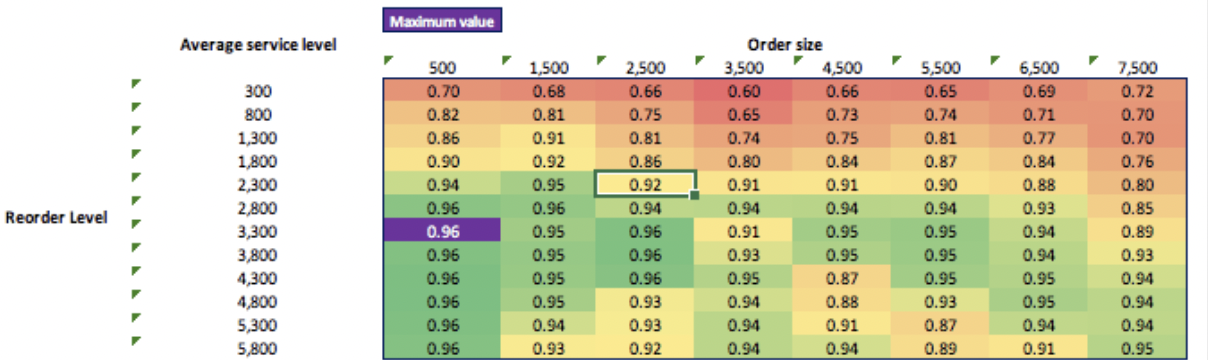

Simulation Model: This is a probability-based approach designed for estimating the safety stock levels of critical products. This model includes various parameters such as total cost or number of stockout days.

Phase 3: Develop and implement the new inventory optimisation tool

The SprintlyWorks team developed the tool considering the above parameters and currently is in use by the inventory ordering team.

Results

SprintlyWorks team enabled BeverageCo. to drive business benefits from the two approaches of inventory optimization:

Static Model:

- Analysis and comparison of the current situation with the ideal situation

- Provides an idea of the ordering volume and frequency considering the shelf-life requirements

Simulation Model:

- Provision for renegotiating with suppliers regarding the lead time variation of certain products

- Reassessing the committed shelf-life requirements on the basis of simulating different scenarios

- Increased control over inventory in terms of pre-defined safety stock levels.

Testimonial

The team brought outside-in view, evaluated our business activities, and found out the most essential from the big data elements.